Máquina de moldagem de perfis de painéis de barreira acústica

A máquina de moldagem por rolamento de painéis de barreira sonora acústica é projetada para fazer os painéis de barreira sonora em lote totalmente automaticamente.Os painéis acústicos são a solução mais popular para espaços onde o eco e a reverberação criam tanto ruído ambientalAo absorverem o som, os painéis acústicos minimizam os reflexos sonoros e criam um ambiente acústico mais confortável onde a fala é inteligível e o volume é reduzido.Aqui vamos tomar alguns perfil desenho por exemplo para mostrar-lhe como fazer máquina para fazer a produção:

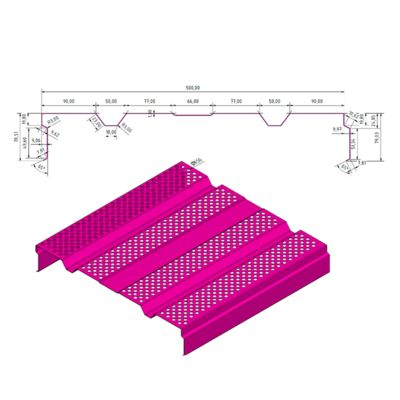

Para os painéis de barreira sonora, na maioria das vezes existem três partes compostas para ser: fundo, cobertura e canal de conexão.

Então a máquina de moldagem de rolamento, precisamos de ferramentas seguintes:

1Uma linha de produção: máquina de perfurar.fazer a folha com furos e, em seguida, para a máquina de moldagem de rolamento ou recoiler.

2A segunda opção, se quiser acelerar a taxa de produção, é recolher o perfurado e depois fazer o laminado para o perfil inferior e o perfil traseiro.

3.Se a sua área de fábrica é limitada, podemos fazer o perfuramento e laminamento formando por uma máquina.

Na parte seguinte, apresentamos um por um:

Parte 1: Linha de punção:

Fluxo de trabalho: Descolador hidráulico - Servo-alimentador - Punção - Tensão e recoiler

Para o descoiler, você pode escolher um manual ou um hidráulico, recomendamos melhor tipo automático.

Para a máquina de perfurar, você pode escolher uma marca famosa da China ou uma normal.

Recoler é necessário, automático com sistema de tensão.

Parte 2: Máquina de moldagem por rolamento

Máquina de moldagem de painéis de barreira de som, podemos personalizar totalmente de acordo com suas necessidades:

Para a parte da transmissão, pode utilizar o tipo de caixa de velocidades ou o tipo de cadeia.

Para o corte, você pode optar por usar o corte de rastreamento servo ou o projeto de corte de parada.

Aqui tomamos o tipo econômico, por exemplo, para mostrar como projetamos a máquina:

1Sobre a cadeia: Vantagem: Este projeto tornará a máquina mais forte, para prolongar a vida útil da máquina.

2Para o encontro, usamos um suporte forte para garantir durabilidade e precisão.

3.Para os rolos e o eixo: porca de bloqueio duplo com almofada de empuxo e pinças para garantir que a tampa de bloqueio do rolão não se solta durante a operação do equipamento.Os keynotes do rolo e os keynotes do eixo são bem combinados, e o

Muitas fábricas não têm keynote.

4Para o painel de controlo, normalmente usamos todo o sistema Siemens;

Nós fizemos muitos tipos de painéis de barreira acústica de som perfis, aqui estão mais perfis de desenho para sua referência:

Podemos fazer totalmente Painéis de Barreira de Som Acústico Profil Rolling Forming Machine de acordo com o seu projeto.

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!