Máquina de Conformação de Tubos Ovais Intertravados de Aço Galvanizado

Especializada para Eletrodutos e Dutos de Fiação

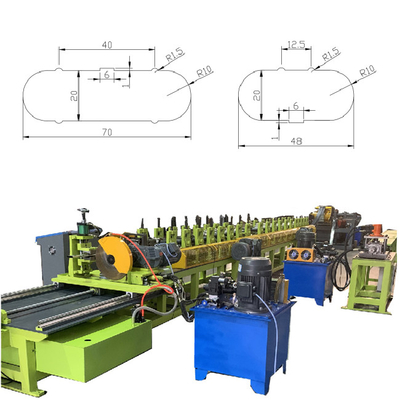

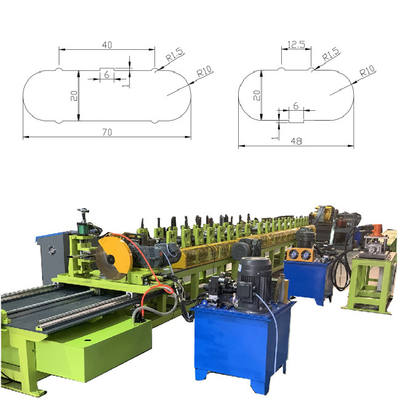

Nosso Máquina de Conformação de Tubos Ovais Intertravados é projetada para precisão e eficiência na produção em massa de tubos ovais de parede fina para eletrodutos ou dutos de fiação. Usando o princípio da conformação por rolo, ela cria tubos ovais intertravados (sem necessidade de soldagem para materiais finos) e integra funções-chave como a redução de diâmetro para facilitar a conexão dos tubos — ideal para projetos que exigem estruturas de tubos confiáveis e sem costura.

Aplicação Principal: Tubos Ovais para Eletrodutos e Dutos de Fiação

Os tubos ovais intertravados produzidos por esta máquina servem a dois papéis críticos em sistemas elétricos:

- Eletrodutos: Protegem os fios elétricos contra danos externos (por exemplo, impacto, umidade) com uma estrutura fechada e intertravada que garante a segurança a longo prazo.

- Dutos de Fiação Elétrica: Organizam e roteiam a fiação em ambientes industriais ou comerciais, aproveitando a forma oval para instalação que economiza espaço e fácil acesso.

Preparamos perfis de desenho detalhados dos tubos ovais para sua referência — entre em contato conosco para verificar se as dimensões correspondem às necessidades do seu projeto elétrico.

Configuração Completa da Máquina: Do Desenrolamento ao Tubo Acabado

A Máquina de Conformação de Tubos Ovais Intertravados integra todos os componentes necessários para a produção de tubos ovais de ponta a ponta:

- Desenrolador Manual de 3TON: Desenrola bobinas de matéria-prima (aço galvanizado ou pré-pintado) de forma constante, fornecendo um suprimento estável de material.

- Unidade de Alimentação: Controla a velocidade e o alinhamento da alimentação da matéria-prima, com suporte de operação manual para ajustes fáceis.

- Sistema de Resfriamento: Evita o superaquecimento dos rolos e materiais durante a conformação, protegendo os componentes da máquina.

- Sistema de Conformação por Rolo: O coração da máquina, moldando chapas de metal planas em perfis ovais por meio de rolos de precisão com uma costura intertravada.

- Sistema de Transmissão: Aciona as unidades de conformação por rolo e alimentação de forma síncrona, mantendo uma velocidade de conformação uniforme.

- Sistema de Corte: Corta os tubos ovais acabados no comprimento desejado, garantindo dimensões consistentes.

- Sistema de Controle: Centraliza a operação de todos os componentes, simplificando os ajustes de parâmetros.

- Rack de Suporte de Saída: Suporta os tubos acabados ao saírem da máquina, evitando dobras ou danos.

Materiais Compatíveis e Limites de Espessura

| Característica |

Especificação |

| Materiais Adequados |

Aço galvanizado ou aço pré-pintado (resistente à corrosão) |

| Espessura Aplicável ao Intertravamento |

0,3-1,2 mm (sem necessidade de soldagem) |

| Espessura Acima de 1,2 mm |

Requer emparelhamento com sistema de soldagem ou máquina de conformação secundária |

Personalização Chave: Design de Troca Rápida para Tubos de Vários Tamanhos

Nosso design de troca rápida permite a produção econômica de vários tamanhos:

- Os rolos e eixos são montados em uma estrutura de base dedicada para fácil troca de tamanho

- Reduz o investimento em componentes compartilhados duplicados

- Disponível em configurações econômicas e de alta qualidade

Fácil Conexão de Tubos: Máquina de Redução de Diâmetro para Sobreposição Segura

A máquina de redução de diâmetro integrada permite conexões de tubos sem costura:

- Reduz o diâmetro de uma extremidade do tubo (com nervuras de reforço) para inserção

- Cria conexões apertadas e seguras sem fixadores adicionais

- Simplifica a instalação e aprimora a estabilidade estrutural

Veja o Processo Inteiro: Solicite o Vídeo de Funcionamento

Entre em contato conosco para acessar um vídeo de funcionamento detalhado mostrando o ciclo completo de produção, do desenrolamento ao tubo acabado.

Personalize para Suas Necessidades

Podemos adaptar a máquina às suas necessidades específicas de dimensões de tubos, espessuras de materiais ou necessidades de produção. Entre em contato com nossa equipe para obter detalhes sobre parâmetros, perfis de desenho ou opções de personalização.

Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!  Por favor verifique seu email!

Por favor verifique seu email! Por favor verifique seu email!

Por favor verifique seu email!